Road, Aviation & Pathway Construction

“Soil stabilization” is a broad category that in many cases encapsulates much of what we do. However, the specific applications we carry out greatly depend on the needs of our diverse client base. Our body of work consists of roads, runways, taxiways, aprons, helipads, hardstands, parking lots, trails, pathways, loading & storage areas and recreational applications.

Cold In-Place Asphalt Reclamation

Traditional, asphalt-based road re-construction processes are simple yet wasteful: The most cost-effective asphalt application is known as an “overlay.” This is a process of putting new asphalt down on top of the bad, failing asphalt. It is considered a low-cost, quick fix and provides the newly paved look that drivers are seeking. It is, however, a BandAid because the problems beneath will quickly rise to the surface. The 2nd most traditional asphalt application is known as “remove and replace or R&R.” As the name implies, this process involves removing (milling out) the existing asphalt and replacing it will new asphalt. Although a better option for longer lasting pavement than an Overlay, there are two primary reasons why R&R is both wasteful and inefficient:

- Asphalt millings (pulverized asphalt) are a relatively high-grade material if properly recycled. Just because a surface is cracked up and degrading, doesn’t mean that the material itself can’t be rehabilitated and reused. The cost and time needed to mill out and remove/dispose of the failing asphalt is significant.

- This approach doesn’t address the root cause of the asphalt failure problems with the base. Rather than addressing these issues at the base, “R&R” is simply a short-term solution to long-term problems the will result in required maintenance early in the roads life cycle.

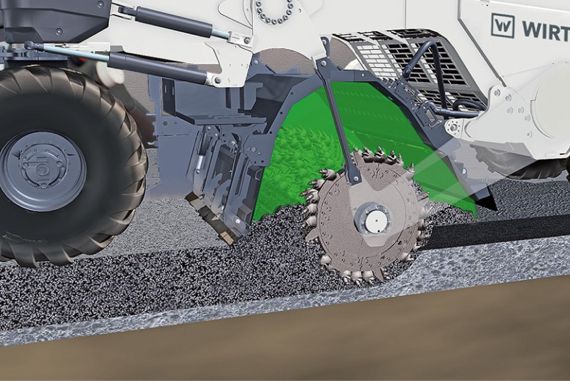

By leveraging a reclaimer-driven process called cold in-place asphalt reclamation LANDLOCK® is able to:

- Eliminate wasteful costs and reduce time associated with removing and disposing of the failing asphalt.

- Address failures at the base by integrating the asphalt millings (a high-quality material) into the base at a 1 to 1 ratio. Meaning, if there are 3’’ of asphalt, the reclaimer will pulverize a total 6’’.

Many counties, villages, and townships around the country are doing something new referred to as “Crush & Shape” a process of literally pulverizing an asphalted road and then grading, shaping and compacting. This essentially turns traditional asphalt roads back to gravel which will result in far more annual maintenance to control, erosion, washout, settlement, gravel loss and dust.

LANDLOCK’s® cold in-place asphalt reclamation process is one of the most cost effective, high performing and environmentally-friendly alternatives for rehabilitating failing asphalted roads in support crush & shape programs.